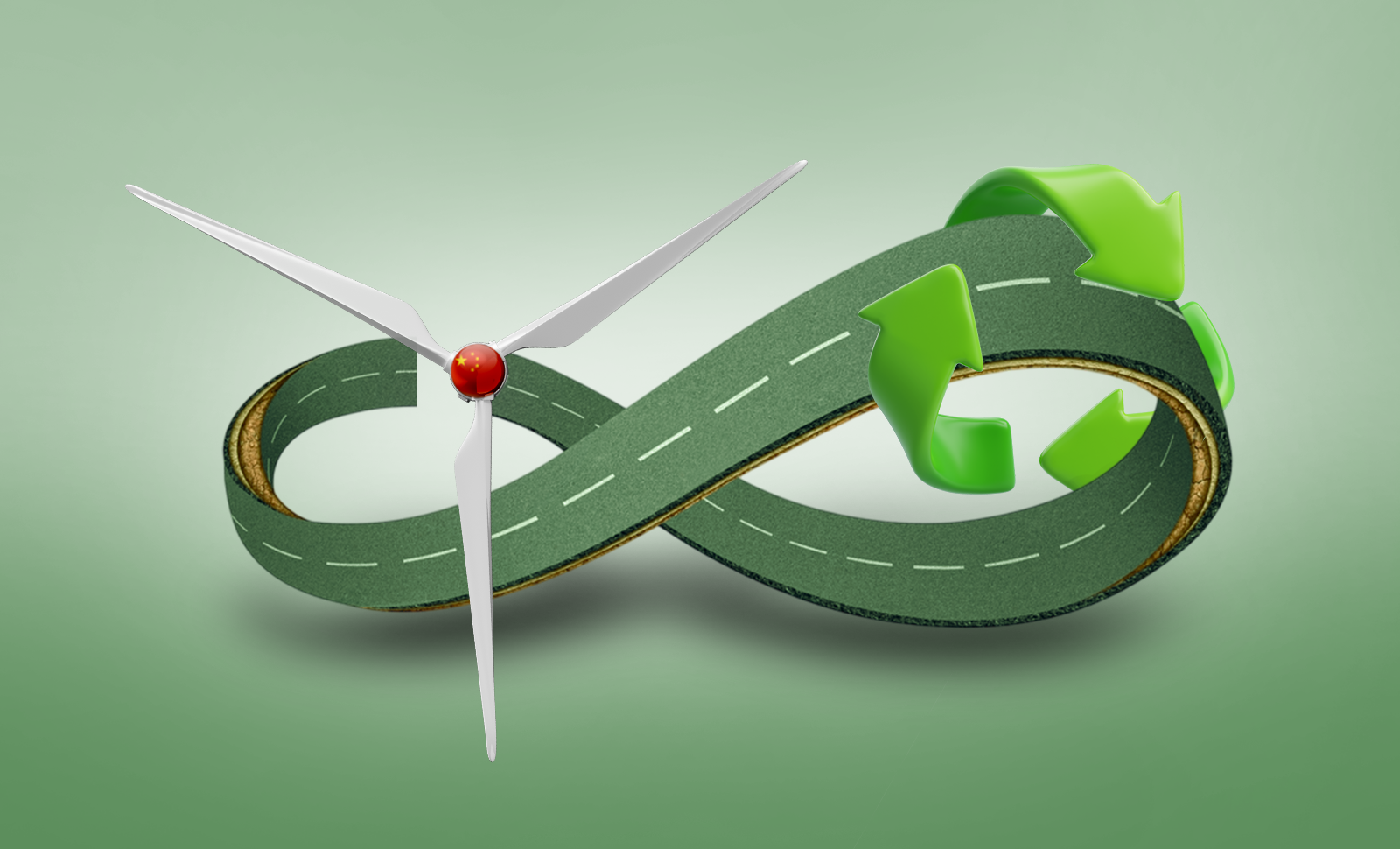

As the global push for renewable energy intensifies, the challenge of managing decommissioned wind turbine blades has become increasingly prominent. In a groundbreaking development, Chinese researchers have unveiled a method to repurpose these massive structures into robust road construction materials, addressing both environmental concerns and infrastructure needs.

The Challenge of Wind Turbine Blade Disposal

Wind turbine blades, typically designed to last between 20 to 25 years, are constructed from composite materials like fiberglass, carbon fiber, and epoxy resin. These components, while offering strength and durability, pose significant recycling challenges due to their complex composition and resistance to degradation. As a result, a scalable and efficient recycling solution has remained elusive.

Pioneering Research from Lanzhou

A dedicated team from the Lanzhou Institute of Chemical Physics at the Chinese Academy of Sciences, led by Tang Zhicheng, has spent five years developing an innovative approach to this issue. Their technique involves physically crushing the retired blades and applying chemical treatments to modify the composite materials. This process transforms the blades into components suitable for inclusion in asphalt mixtures and cement concrete, effectively turning waste into a valuable resource.

Successful Implementation in Road Construction

In September 2024, the research team collaborated with a local construction company to test this novel material on a section of the Qingfu Highway in Lanzhou, Gansu Province. After more than five months of use, the modified asphalt pavement exhibited no signs of cracks, rutting, or material detachment, demonstrating the durability and feasibility of this recycling method.

Implications for Sustainable Development

This advancement not only offers a practical solution for managing decommissioned wind turbine blades but also contributes to China’s broader environmental objectives. By repurposing these blades into “urban mineral resources,” the initiative supports the nation’s goals of peaking carbon emissions by 2030 and achieving carbon neutrality by 2060. The research team plans to expand this technology through additional demonstration projects, aiming to establish a reliable and scalable method for recycling wind turbine blades on a larger scale.

Final Note

The successful transformation of retired wind turbine blades into durable road materials exemplifies how innovative research can address environmental challenges while enhancing infrastructure. This approach not only mitigates the disposal issues associated with renewable energy equipment but also paves the way for more sustainable construction practices in the future.