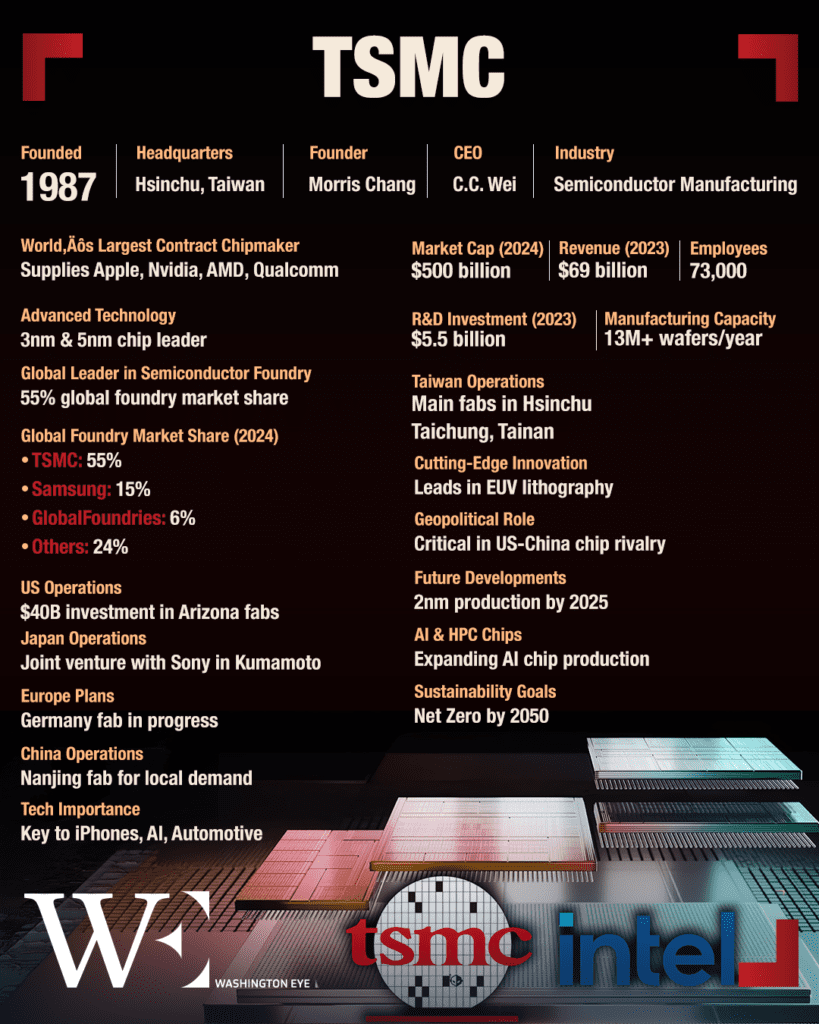

In a landmark move set to reshape the global semiconductor landscape, Taiwan Semiconductor Manufacturing Company (TSMC), the world’s largest contract chipmaker, has announced a monumental $100 billion investment to expand its manufacturing footprint in the United States.

Announced on March 3, 2025, during a press conference at the White House, TSMC’s CEO, C.C. Wei, detailed the company’s ambitious plans. The investment encompasses the construction of three additional chip fabrication plants, two advanced packaging facilities, and a state-of-the-art research and development center in Arizona.

This expansion is poised to create tens of thousands of high-paying jobs and solidify the U.S.’s position in the semiconductor industry. This new commitment supplements TSMC’s prior $65 billion investment in Arizona, bringing the company’s total U.S. investment to a staggering $165 billion. The initial phase saw the establishment of three chip manufacturing plants, with the first commencing high-volume production of 4-nanometer chips in late 2024. The forthcoming facilities are slated to produce cutting-edge 2-nanometer semiconductors, essential for next-generation technologies such as artificial intelligence (AI), mobile computing, and critical infrastructure.

Catalysts Behind the Investment

The U.S.-China tech rivalry has intensified, with semiconductors at the heart of national security and economic strategies. By expanding its U.S. operations, TSMC aims to mitigate risks associated with geopolitical uncertainties, particularly concerning Taiwan’s delicate position amid U.S.-China tensions. The U.S. government has been proactive in bolstering domestic semiconductor production. The previous administration’s CHIPS and Science Act laid the groundwork, offering subsidies and incentives to chipmakers. The current administration, under President Donald Trump, has adopted a more aggressive stance, threatening high tariffs on imported semiconductors to encourage domestic manufacturing.

TSMC’s investment aligns with these policy shifts, aiming to preempt potential tariffs and capitalize on available incentives. The global surge in demand for advanced technologies, including AI, autonomous vehicles, and Internet of Things (IoT) devices, has heightened the need for sophisticated semiconductors. TSMC’s expansion is strategically positioned to meet this escalating demand, ensuring a stable supply chain for U.S. tech giants like Apple, Nvidia, AMD, and Qualcomm.

The expansion is expected to support approximately 40,000 construction jobs over the next four years and generate tens of thousands of permanent high-tech positions in advanced chip manufacturing and research. This influx of employment opportunities is projected to stimulate local economies and contribute significantly to the U.S. GDP. By producing some of the world’s most advanced semiconductors on U.S. soil, TSMC’s facilities will bolster America’s leadership in critical technology sectors, including AI, quantum computing, and advanced telecommunications. This domestic production capability is vital for maintaining competitiveness in the global tech arena. The COVID-19 pandemic and subsequent supply chain disruptions highlighted the vulnerabilities of over-reliance on specific regions for critical components. TSMC’s U.S. expansion enhances supply chain resilience, reducing dependence on overseas manufacturing and mitigating risks associated with geopolitical conflicts or natural disasters.

Apple has unveiled plans to invest over $500 billion in the U.S. over the next four years, including the construction of a server factory in Texas and the creation of 20,000 jobs. This move underscores Apple’s strategy to localize its supply chain and mitigate risks associated with international trade tensions. A consortium comprising Oracle, OpenAI, and SoftBank has announced the formation of “Stargate,” a venture dedicated to expanding AI infrastructure in the U.S., with a projected investment of $500 billion in the coming years. This initiative highlights the industry’s recognition of the U.S. as a pivotal hub for technological innovation and infrastructure development.

Scaling operations to this magnitude requires a vast pool of skilled labor. Addressing potential talent shortages in specialized fields like semiconductor fabrication and advanced research will be crucial. Collaborative efforts between industry, academia, and government will be essential to cultivate and attract the necessary workforce. Semiconductor manufacturing is resource-intensive, raising concerns about environmental sustainability.

Implementing eco-friendly practices, optimizing resource utilization, and ensuring compliance with environmental regulations will be imperative to mitigate ecological impacts. TSMC’s U.S. expansion may influence global semiconductor pricing, supply dynamics, and competitive strategies.

Competitors may respond with their investment plans or seek to innovate alternative solutions, potentially reshaping the industry’s landscape. TSMC’s $100 billion investment in U.S. manufacturing marks a pivotal moment in the semiconductor industry, reflecting a confluence of strategic foresight, policy alignment, and market demand.

As the digital age accelerates, such investments are crucial to ensuring technological leadership, economic prosperity, and national security.

Daily euro times